-40%

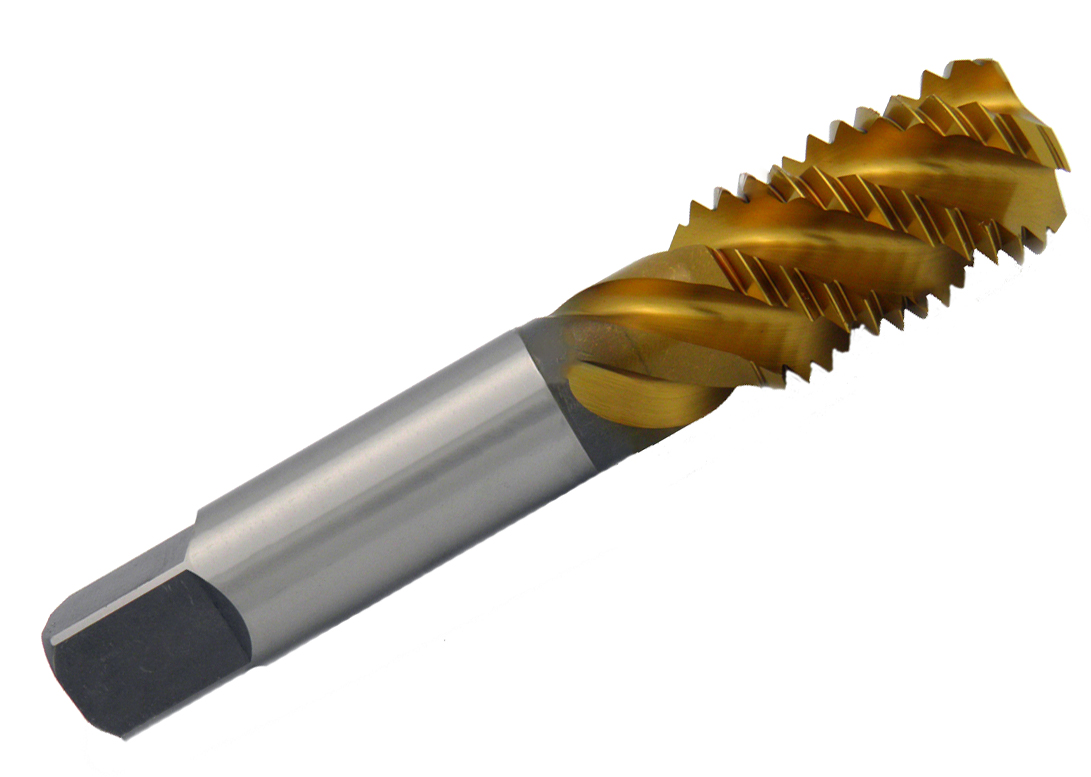

M8X1.25 D5 HIGH SPEED STEEL 3 FLUTE DIN LENGTH TICN COATED SPIRAL POINT PLUG TAP

$ 13.72

- Description

- Size Guide

Description

M8X1.25 D5 3 FLUTE HIGH SPEED STEEL DIN LENGTH TICN COATED SPIRAL POINT PLUG TAP61209

MADE IN USA

Technical Specifications

Type

HPT High Performance Tap

Class

Metric

Brand Name

MORSE® Cutting Tools

Flute Type

Spiral Point

Finish

TiCN

Style

UNC - Unified Coarse Thread Series

Pitch Diameter Limit

D5

Chamfer

Plug

Pitch

1.25

Chamfer Length

3 to 5 Threads

Harmonized Tariff Code

8207.40

List No.

2088MC

Diameter

M8

Material

Powder Metallurgy High Speed Steel

Overall Length

90mm

Origin

Made In U.S.A.

Number of Flutes

3

Coating

Titanium Carbonitride

For Use With

DIN Length - Steel, Steel Alloys, Stainless Steel, Titanium Alloys and Wide Variety of Materials up to 36Rc Hardness

Package Quantity

1

Thread Length

20mm

Neck Length

15mm

UPC Code

686125612092

HPT - High Performance Tap - DIN Length

Recommended for steels, steel alloys, stainless steels, titanium alloys and a wide variety of materials up to 36Rc hardness.

Spiral Point Taps

are designed fo refficient tapping of through holes and blind holes with adequate depth for chip accumulation at the bottom of the hole. The shearing action of the point provides freer cutting action and ejects the chips ahead of the tap, eliminating chip evacuation problems and chip damage to the threads. Shallower flutes also result in greater tap strength, allowing for higher cutting speeds.

Plug Style

(3-5 thread chamfer) is the most common chamfer used for tapping applications in through holes and blind holes with sufficient bottom clearance.

CNC Reduced Neck Design

enhances chip evacuation and cutting fluid flow to the cutting teeth for reduced friction, heat and galling. Also reduces contact between the tap the work piece.

P/MPowder Metallurgy High Speed Steel

Premium Steel Engineered For:

Hardness / Wear Resistance / Tool / Heat Resistance / Toughness and Strength / Performance under Difficult Cutting Conditions / Higher Cutting Speeds / Increased Productivity