-40%

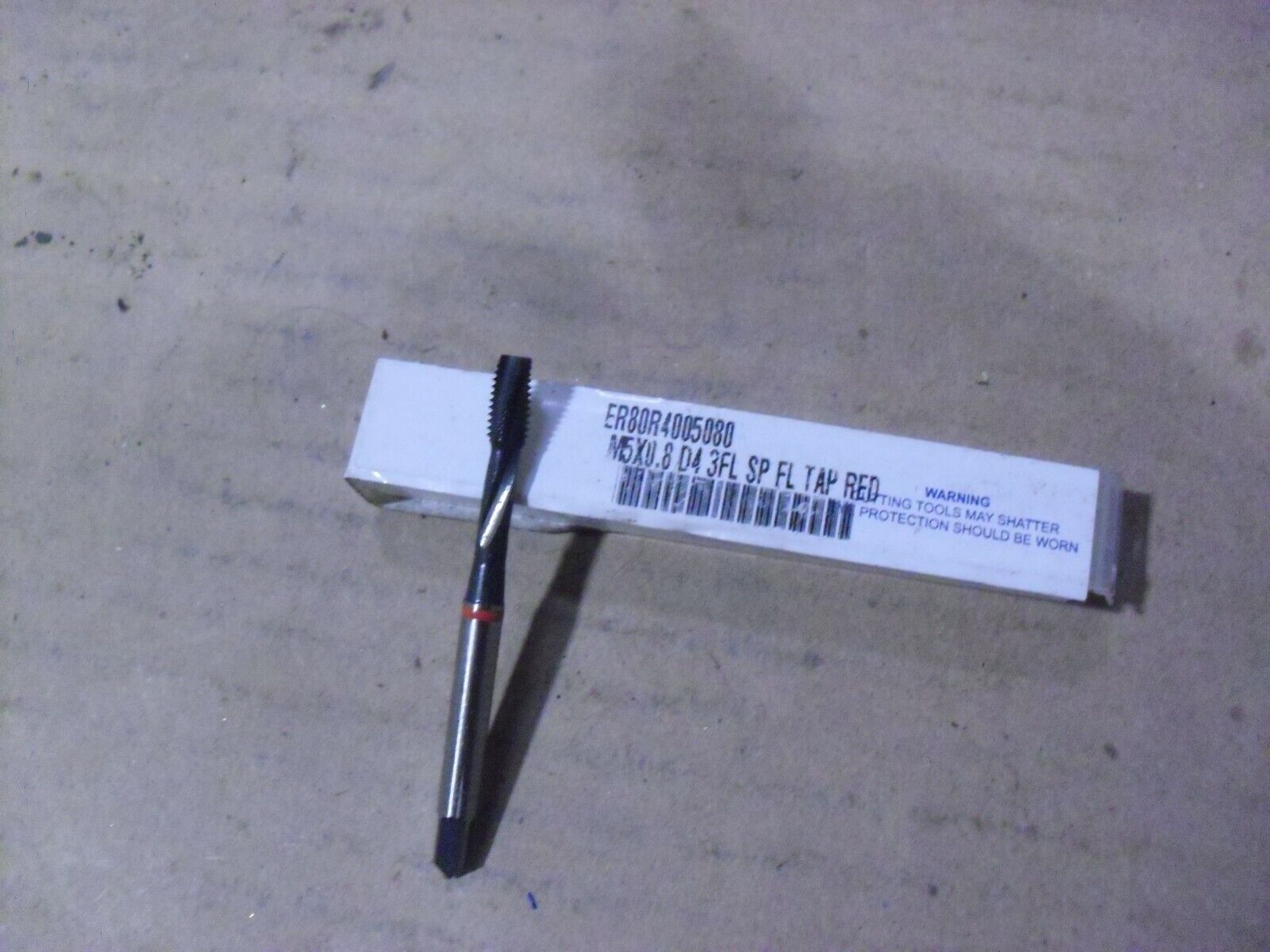

M5 x 0.8 + 0.03 High Speed Steel Titanium Coated Machine Spiral Point Taps

$ 5.16

- Description

- Size Guide

Description

DocumentSpecifications:Thread Size: M5 x 0.8 + 0.03Thread Length: 18mm / 0.71"Square End Size: 4mm / 0.16"Total Length: 63mm / 2.48"Material: Cobalt High Speed Steel (HSS-CO)Finish: Titanium CoatedNumbers of Flutes: 3 FlutesCutting Direction: Right HandPackage Content: 1pcs x Spiral Point TapsDescriptions:Spiral point design, downward chip removal. Right hand thread cutting, clear threads, fast tapping with accuracy. Enlarge the tap to suit the workpiece that needs electroplating or sandblasting after tapping. According to the thickness of the coating, an amplification of 0.03-0.1mm is generally used. High speed steel tool has high hardness and toughness, wear resistance and heat resistance. Titanium coating provides excellent corrosion resistance, greatly improves wear resistance and hardness, and reduces the coefficient of friction.Suitable for processing through-hole threads. For drilling and tapping aluminum, die steel, stainless steel, bronze, hard plastics, etc.. Recommended feed rate: general steel: 6-15m/min; harder steel: 5-10m/min; stainless steel: 2-7m/min; cast iron: 8-10m/min. The torque caused by too fast feed speed is too large, which can easily cause the tap to breakUsed on drilling and tapping machines, CNC and milling machines. Use with tapping oil to get higher quality threads and more durable taps. Machine taps are suggested to be used with tap collets with overload protection. Hand use is easy to cause breakage to the tap due to uneven force. Taps are prone to chipping or breaking due to speed overload or non-vertical tapping. Use the correct tapping tools, such as tap wrench, tapping machine. Micro taps (such as M1-M3.5) are mainly used in clocks and watches, tapping wood and soft metals with lower hardness.

M6 x 1 Spiral Point Threading Tap H2 HSS TICN Coated DIN371/376 2pcs

USD

15.81

M4x0.7 Cobalt High Speed Steel Titanium Plated Machine Spiral Point Thread Tap

USD

12.17

M6 x 1.0 Spiral Point Threading Tap H2 Tolerance High Speed Steel TICN Coated

USD

8.85

M6 x 1 Spiral Point Threading Tap H2 High Speed Steel TICN Coated DIN371/376

USD

11.66

M6x1 Cobalt High Speed Steel Titanium Plated Machine Spiral Point Thread Tap

USD

13.35

M12 x 1.75 Spiral Point Threading Tap H2 High Speed Steel TICN Coated DIN371/376

USD

15.43

M5 x 0.8 + 0.03 High Speed Steel Titanium Coated Machine Spiral Point Taps

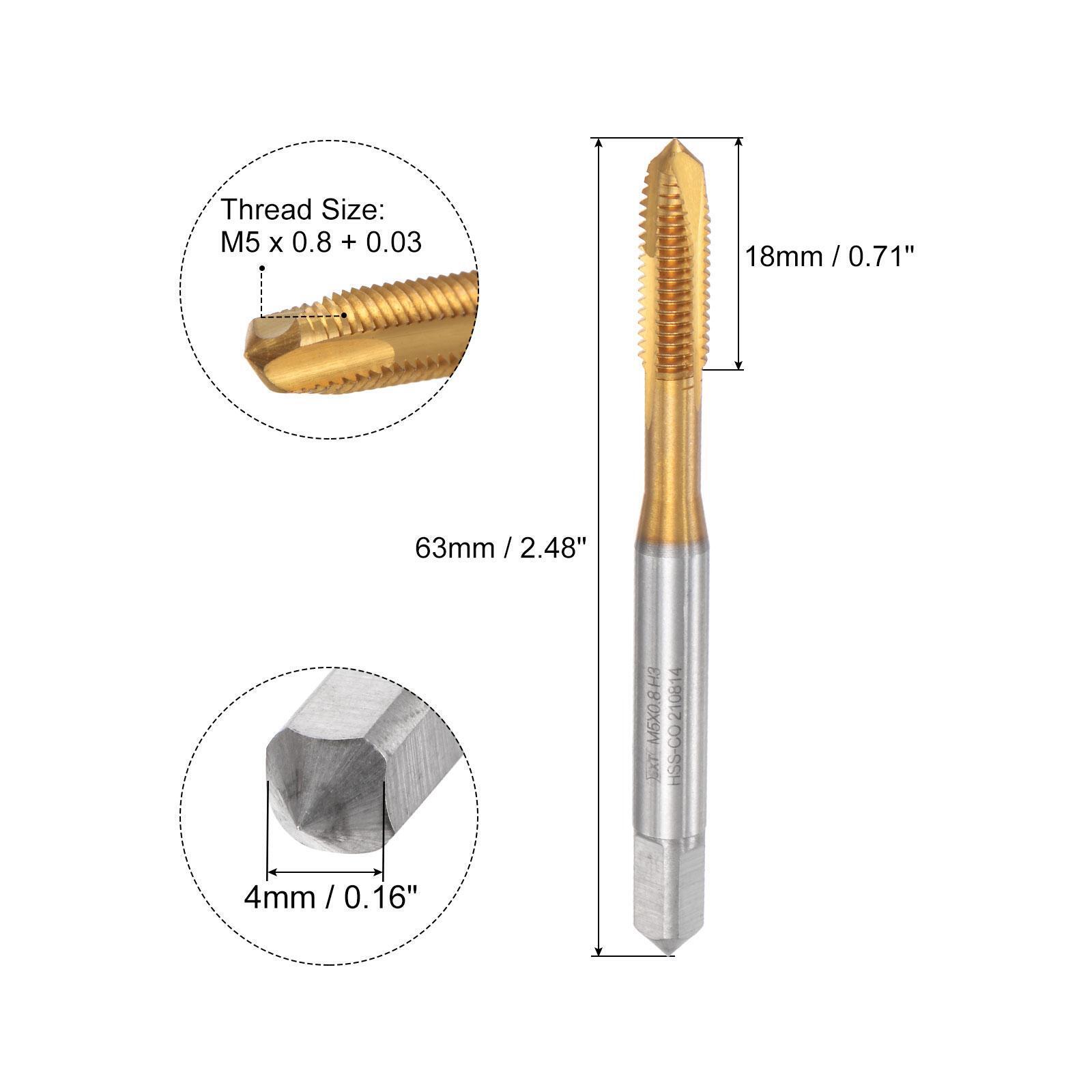

Specifications:

Thread Size: M5 x 0.8 + 0.03

Thread Length: 18mm / 0.71"

Square End Size: 4mm / 0.16"

Total Length: 63mm / 2.48"

Material: Cobalt High Speed Steel (HSS-CO)

Finish: Titanium Coated

Numbers of Flutes: 3 Flutes

Cutting Direction: Right Hand

Package Content: 1pcs x Spiral Point Taps

Descriptions:

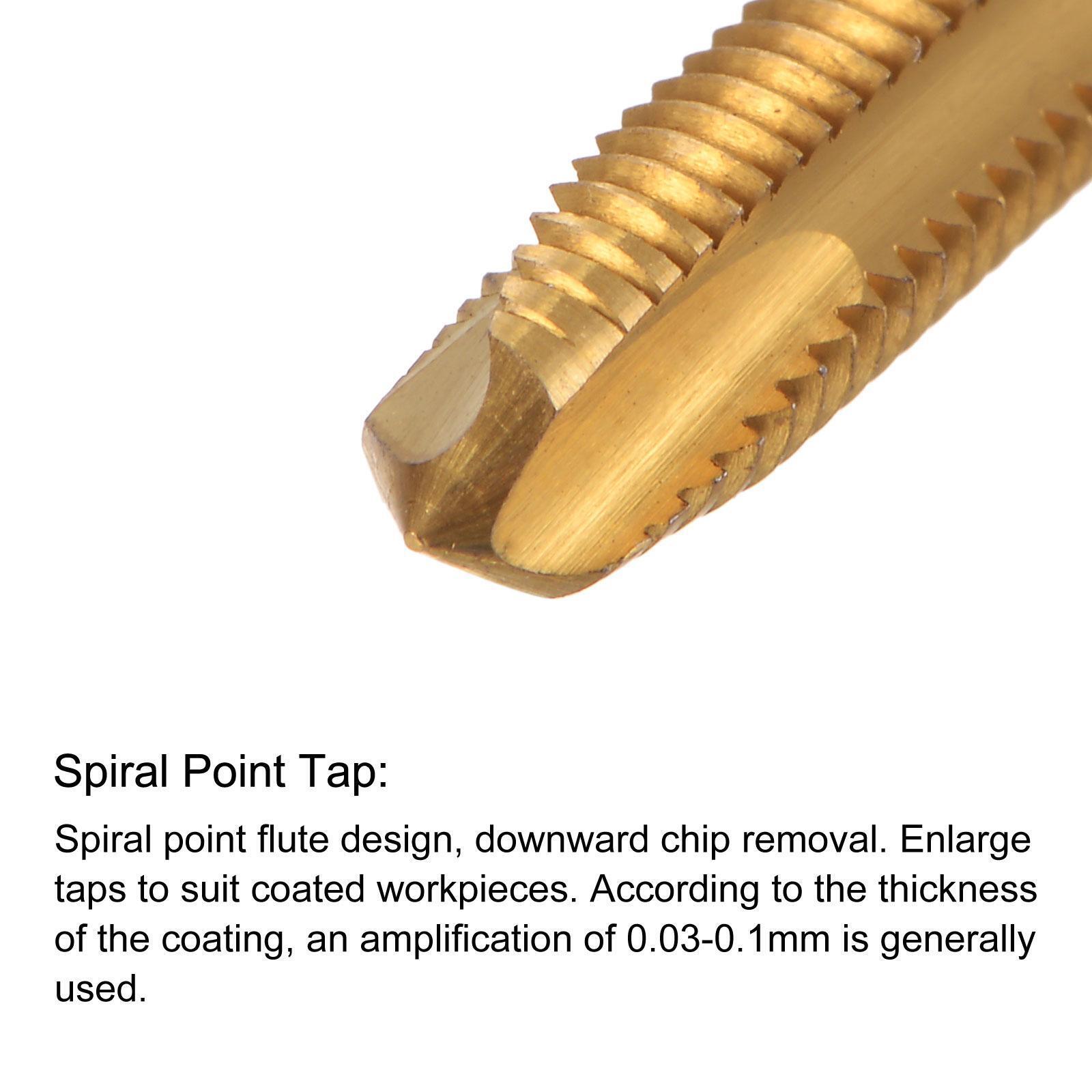

Spiral point design, downward chip removal. Right hand thread cutting, clear threads, fast tapping with accuracy. Enlarge the tap to suit the workpiece that needs electroplating or sandblasting after tapping. According to the thickness of the coating, an amplification of 0.03-0.1mm is generally used.

High speed steel tool has high hardness and toughness, wear resistance and heat resistance. Titanium coating provides excellent corrosion resistance, greatly improves wear resistance and hardness, and reduces the coefficient of friction.

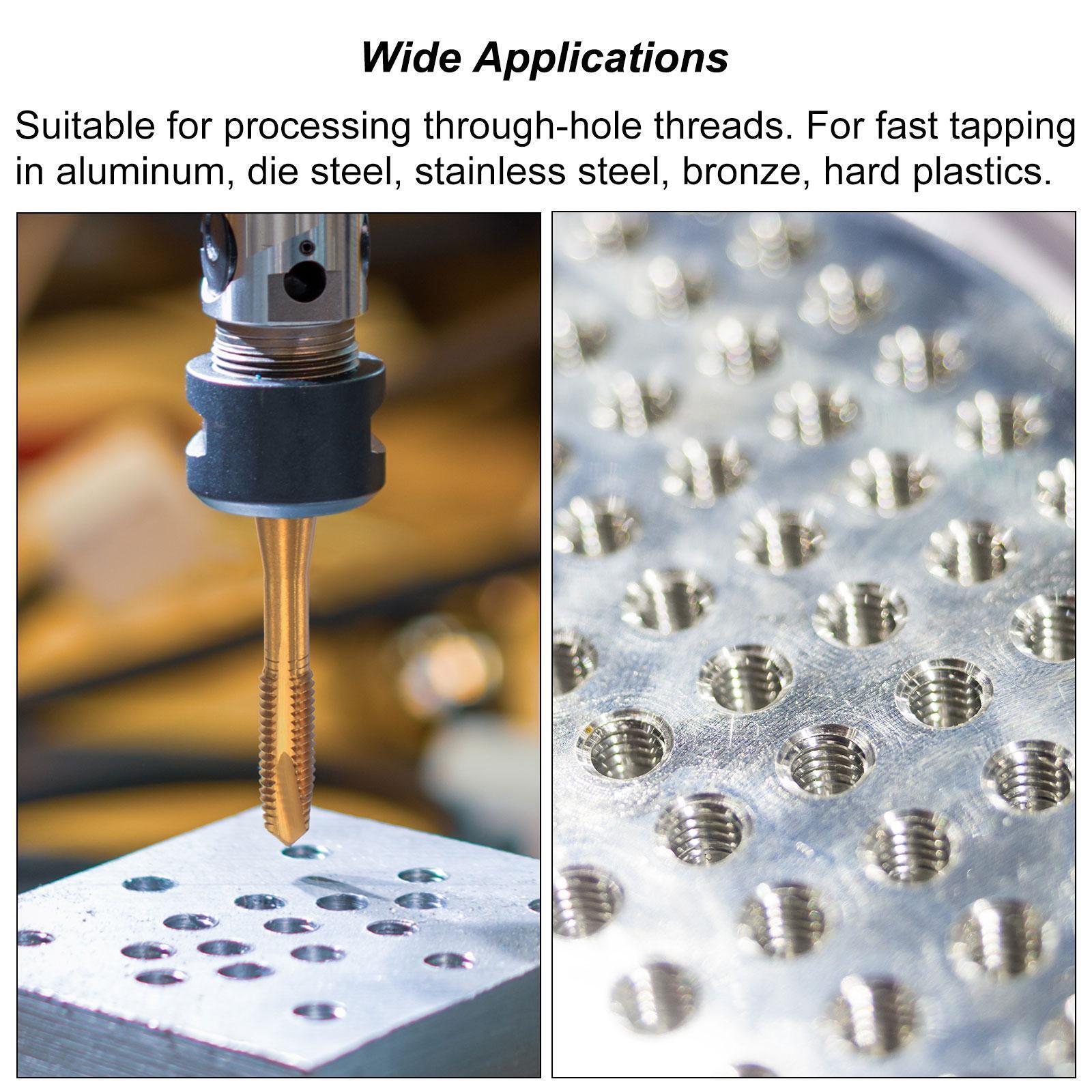

Suitable for processing through-hole threads. For drilling and tapping aluminum, die steel, stainless steel, bronze, hard plastics, etc.. Recommended feed rate: general steel: 6-15m/min; harder steel: 5-10m/min; stainless steel: 2-7m/min; cast iron: 8-10m/min. The torque caused by too fast feed speed is too large, which can easily cause the tap to break

Used on drilling and tapping machines, CNC and milling machines. Use with tapping oil to get higher quality threads and more durable taps. Machine taps are suggested to be used with tap collets with overload protection. Hand use is easy to cause breakage to the tap due to uneven force.

Taps are prone to chipping or breaking due to speed overload or non-vertical tapping. Use the correct tapping tools, such as tap wrench, tapping machine. Micro taps (such as M1-M3.5) are mainly used in clocks and watches, tapping wood and soft metals with lower hardness.

Hot Item

M4x0.7 Cobalt High Speed Steel Titanium Plated Machine Spiral Point Thread Tap

USD 12.17

M6 x 1.0 Spiral Point Threading Tap H2 Tolerance High Speed Steel TICN Coated

USD 8.85

M12 x 1.75 Spiral Point Threading Tap H2 High Speed Steel TICN Coated DIN371/376

USD 15.43

M6 x 1 Spiral Point Threading Tap H2 High Speed Steel TICN Coated DIN371/376

USD 11.66

M6x1 Cobalt High Speed Steel Titanium Plated Machine Spiral Point Thread Tap

USD 13.35

Payment

We accept eBay payment.

Please do not email us to ask for other payment option.

We appreciate prompt payment and look forward to your business in the future. Unpaid item will be filed without receiving payment in 7 days from listing ended.

Shipping

Usually we ship your order out within 24 hours in business day.

For shipping and handling charges (S&H) for specific item, please refer to the item listing page for more details.

Please make sure your shipping address is correct. We are not responsible for any loss in transit if a wrong address is provided.

Return Policy

Returns for exchange are permitted and must be initiated by the buyer within 30 days upon receipt.

If you would like to return your product(s) for repair / replacement / refund, please kindly contact our customer service representatives via email for an authorized RMA number. Your returned product(s) will not be processed without a completed RMA.

About Us

We are continually expanding our product selection to better serve your need.

We look forward to providing the best sevice to you - our dear customers, so take a look around our store and find the product that you want. You can put your trust in us!

If you need any help or have any suggestions, please don't hesititate to contact us anytime , we will reply you within 24 hours and try the best to help you.

Description

Policy

M5 x 0.8 + 0.03 High Speed Steel Titanium Coated Machine Spiral Point Taps

Specifications:

Thread Size: M5 x 0.8 + 0.03

Thread Length: 18mm / 0.71"

Square End Size: 4mm / 0.16"

Total Length: 63mm / 2.48"

Material: Cobalt High Speed Steel (HSS-CO)

Finish: Titanium Coated

Numbers of Flutes: 3 Flutes

Cutting Direction: Right Hand

Package Content: 1pcs x Spiral Point Taps

Descriptions:

Spiral point design, downward chip removal. Right hand thread cutting, clear threads, fast tapping with accuracy. Enlarge the tap to suit the workpiece that needs electroplating or sandblasting after tapping. According to the thickness of the coating, an amplification of 0.03-0.1mm is generally used.

High speed steel tool has high hardness and toughness, wear resistance and heat resistance. Titanium coating provides excellent corrosion resistance, greatly improves wear resistance and hardness, and reduces the coefficient of friction.

Suitable for processing through-hole threads. For drilling and tapping aluminum, die steel, stainless steel, bronze, hard plastics, etc.. Recommended feed rate: general steel: 6-15m/min; harder steel: 5-10m/min; stainless steel: 2-7m/min; cast iron: 8-10m/min. The torque caused by too fast feed speed is too large, which can easily cause the tap to break

Used on drilling and tapping machines, CNC and milling machines. Use with tapping oil to get higher quality threads and more durable taps. Machine taps are suggested to be used with tap collets with overload protection. Hand use is easy to cause breakage to the tap due to uneven force.

Taps are prone to chipping or breaking due to speed overload or non-vertical tapping. Use the correct tapping tools, such as tap wrench, tapping machine. Micro taps (such as M1-M3.5) are mainly used in clocks and watches, tapping wood and soft metals with lower hardness.

M6 x 1 Spiral Point Threading Tap H2 HSS TICN Coated DIN371/376 2pcs

USD

15.81

M4x0.7 Cobalt High Speed Steel Titanium Plated Machine Spiral Point Thread Tap

USD

12.17

M6 x 1.0 Spiral Point Threading Tap H2 Tolerance High Speed Steel TICN Coated

USD

8.85

M6 x 1 Spiral Point Threading Tap H2 High Speed Steel TICN Coated DIN371/376

USD

11.66

M6x1 Cobalt High Speed Steel Titanium Plated Machine Spiral Point Thread Tap

USD

13.35

M12 x 1.75 Spiral Point Threading Tap H2 High Speed Steel TICN Coated DIN371/376

USD

15.43

Hot Item

M4x0.7 Cobalt High Speed Steel Titanium Plated Machine Spiral Point Thread Tap

USD 12.17

M6 x 1.0 Spiral Point Threading Tap H2 Tolerance High Speed Steel TICN Coated

USD 8.85

M12 x 1.75 Spiral Point Threading Tap H2 High Speed Steel TICN Coated DIN371/376

USD 15.43

M6 x 1 Spiral Point Threading Tap H2 High Speed Steel TICN Coated DIN371/376

USD 11.66

M6x1 Cobalt High Speed Steel Titanium Plated Machine Spiral Point Thread Tap

USD 13.35

Payment

We accept eBay payment.

Please do not email us to ask for other payment option.

We appreciate prompt payment and look forward to your business in the future. Unpaid item will be filed without receiving payment in 7 days from listing ended.

Shipping

Usually we ship your order out within 24 hours in business day.

For shipping and handling charges (S&H) for specific item, please refer to the item listing page for more details.

Please make sure your shipping address is correct. We are not responsible for any loss in transit if a wrong address is provided.

Return Policy

Returns for exchange are permitted and must be initiated by the buyer within 30 days upon receipt.

If you would like to return your product(s) for repair / replacement / refund, please kindly contact our customer service representatives via email for an authorized RMA number. Your returned product(s) will not be processed without a completed RMA.

About Us

We are continually expanding our product selection to better serve your need.

We look forward to providing the best sevice to you - our dear customers, so take a look around our store and find the product that you want. You can put your trust in us!

If you need any help or have any suggestions, please don't hesititate to contact us anytime , we will reply you within 24 hours and try the best to help you.

On Aug 12, 2022 at 01:41:15 PDT, seller added the following information: